Introduction

Cable glands are tools which are vital when terminating cables in harsh or hazardous settings.

This is where sealing, ingress protection and why cable gland is earthing is required.

Its role is to safely pass a tube, wire, or cable through an enclosure.

They offer strain relief and are also made to include flames or electrical parts which may take place in hazardous settings.

What’s more:

They also act as a seal, stopping exterior impurities from causing any damage to the electrical system and the cable.

Some of these contaminants are:

- fluids,

- dirt,

- dust

Ultimately, they stop cables from being pulled and twisted out of the machine.

That’s because they help to offer a safe and stable connection between the machine and cable to which it’s connected.

In this guide, we will help you better understand how do cable glands work.

Let’s get started.

Cable Glands and Cable Gland Parts

Cable glands are known as ‘mechanical cable entry devices’ that are utilized in conjunction along with wiring and cable for:

- automation systems (e.g. data, telecoms, power, lighting)

- electrical, instrumentation & control

The major functions of a cable gland are to serve as sealing and terminating tool.

It ensures the protection of the enclosures and electrical equipment, including the delivery of:

- Additional environmental sealing

At the cable entry point, keeping the ingress protection rating of the enclosure with the assortment of appropriate accessories committed to doing this purpose

Cable glands in automation machine

- Additional sealing

On the area of the cable arriving the enclosure, if a high level of ingress protection is needed

- Holding force

On the cable to guarantee sufficient levels of mechanical cable ‘pull out’ resistance

- Earth continuity

In the case of an armored cable, once the cable gland features a metallic structure.

In that case, cable gland might be tested to make sure they can endure a sufficient peak short circuit fault current.

- Environmental protection

Through sealing on the exterior cable sheath, excluding moisture and dust from the instrument or electrical enclosure

You see:

Cable glands could be made from non-metallic to metallic materials.

Or it can be a mix of both that might also be resistant to corrosion.

It’s determined by collection to a standard, or by corrosion resistant checks.

If utilized in explosive settings in specific, it’s essential that cable glands are approved for the chosen type of cable.

They must also keep the level of protection of the equipment to which they’re connected.

One of the greatest things about cable glands is that they have an IP68 waterproof function.

That means that can they can be utilized to make watertight exit points from severe and adverse environment enclosures and through bulkheads.

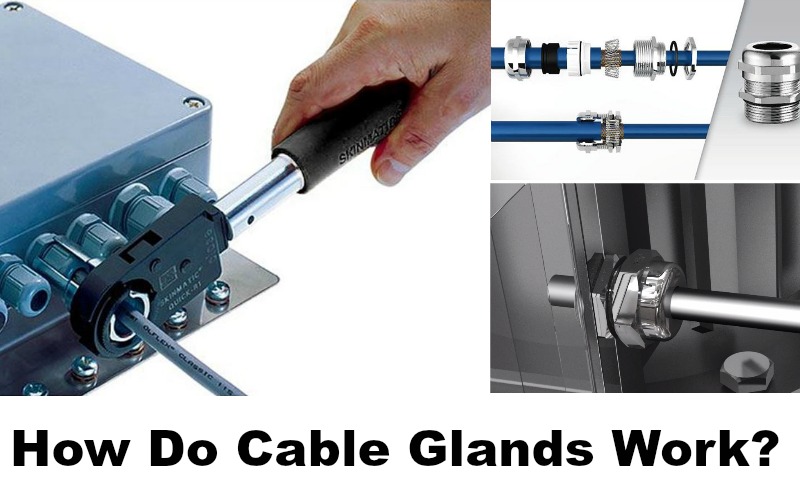

For you to use them:

The cable gland compresses a seal into the round cable.

It stops ingress of particles or water which could cause everlasting damage to the electronic devices.

For example:

If you need to pass a cable onto a waterproof enclosure, you require to drill a hole into the enclosure.

That indeed makes it no longer watertight.

cable glands on the waterproof enclosure

To fix your problem, you can employ a cable gland to make a watertight seal around your cable you’re passing into the enclosure.

An IP68 waterproof function is ideal for cables from 3.5 to 8 millimeters in diameter.

This type of cable glands is made to be installed into the side of the waterproof project enclosure.

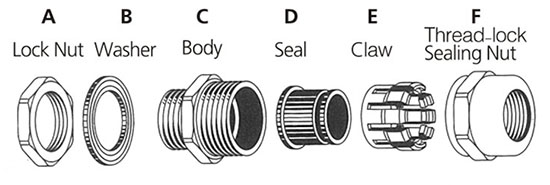

Components of Cable Glands

What are the components of a cable gland?

This is a common question that you might be asking yourself.

components of cable glands

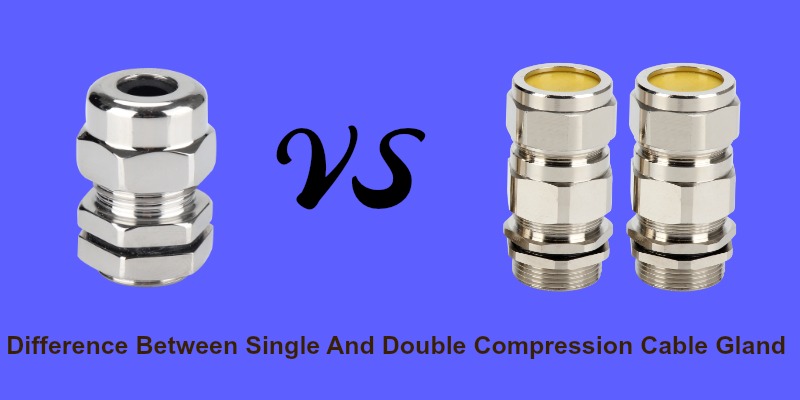

The parts of cable glands are determined according to cable gland types:

- singe compression cable gland and;

- double compression cable gland

Let’s discuss each of them.

In case you didn’t know yet, a single compression cable gland is consumed for lightly armored cables.

They have scope for corrosive and moisture vapor to enter and impact the cable.

Single compression design does not feature cone and cone ring.

You see:

There is only Neoprene rubber seal which provides mechanical support toe gland once you attach the cable.

Lastly, single compression cable glands have:

- gland body nut

- gland body

- flat washer

- check nut

- rubber washer

- rubber seal and;

- neoprene

Those are the parts of a single compression cable gland.

So, have we got that straight?

On the other side:

Double compression has far different from single compression cable gland.

What does this mean?

The cool thing here is:

The double compression cable gland is employed where largely armored wires are getting our or coming into the board.

These type of cable glands provide additional support.

Double compression cable glands feature a double sealing feature.

What’s more:

There is compression at the inner sheath and cable armor.

Therefore, do you want a flameproof or weatherproof cable glands?

Then you need to take into consideration a double compression design.

Take note also that double compression design has a cone ring and cone.

That offers mechanical assistance to the cable.

Now, talking about the parts of a double compression cable gland.

It has the following components:

- check nut

- neoprene rubber seal

- cone ring

- cone

- gland body nut and;

- gland body

Specifications of Cable Glands

Planning to buy your cable gland?

Then you need to remember that there are many cable gland specifications you need to consider.

If you like help with cable gland specifications, here are your choices:

Material

- Stainless Steel

Stainless steel cable glands are corrosion and chemical resistant.

They could have a relatively high-pressure rating

- Steel

Products are made of steel.

- PVC

PVC also was known as polyvinyl chloride is widely utilized material.

It features a smooth surface, good flexibility, and non-toxic characteristics.

A few grades are utilized in chemical and food processes because of the passive nature of PVC.

- Polytetrafluoroethylene (PTFE)

Did you know that Polytetrafluoroethylene is an inexplicable compound?

So what’s the point?

Well, it exhibits a high level of chemical resistance and a low constant of friction.

- Polyamide / Nylon

Nylon is composed of various grades of polyamides.

It is a general purpose material in various uses.

It is resistant and tough and had an excellent pressure rating.

- Brass

Meanwhile, bras come with good strength.

It also features:

- superb high-temperature ductility

- generous cold ductility

- low magnetic permeability

- good bearing properties

- remarkable corrosion resistance and;

- good conductivity

- Aluminum

Aluminum is a bluish-white malleable, ductile light trivalent metallic element.

It has excellent thermal and electrical conductivity.

It also features resistance to oxidation and high reflectivity

Performance

You also need to consider the performance of your cable gland types.

Below, we listed the areas you need to keep in mind.

- Temperature Range

This is the complete needed range of ambient operating temperature.

- Pressure Rating

This is the pressure the cable gland can endure without any leakage.

- Opening Diameter

This is the selection of sizes which the cable gland could accommodate.

- Number of Wires

This is the number of elements the assembly could accommodate.

- Mounting Size

This is the size of the mounting or thread feature.

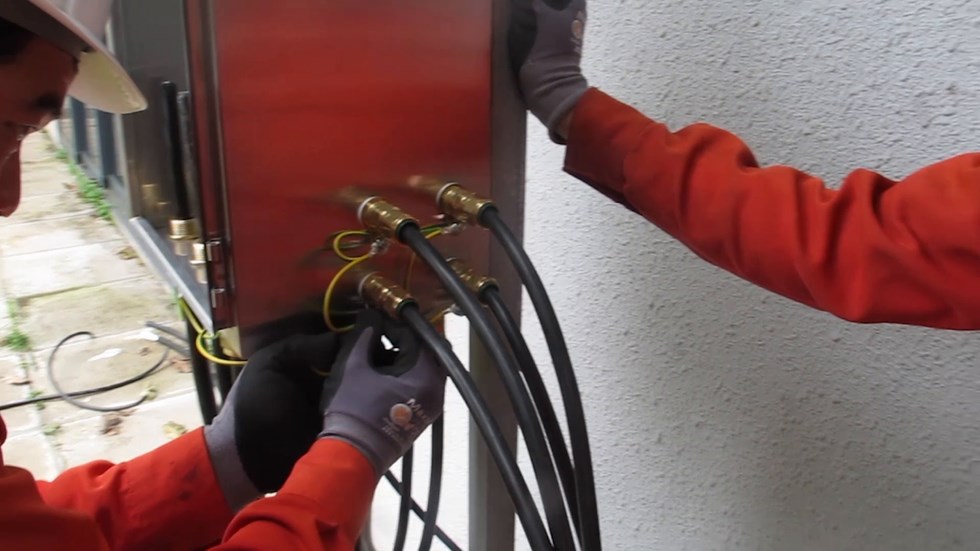

Installation of Cable Gland

Cable gland installation should be carried while following the necessary codes of practice and local regulations.

It should be in accordance along with the guidelines of the manufacturer as well.

Cable gland installation must be carried out through a competent and experienced individual.

He or she must have the necessary know-how and is skilled in the cable gland installation.

Further, training could be facilitated.

Installation of the armored cable gland with earthing tag

This guideline below will help you make sure that the installation of your cable gland guarantees a reliable and safe connection.

Here’s what you need to do:

- Care must be taken to prevent damage to the entry threads when organizing and installing cable glands

- Don’t install cable glands while the circuits are live.

Likewise, following energizing of the electrical circuits, cable glands must not be opened till the circuit has been de-energized safely.

- Cable gland parts aren’t well-matched with those of any other manufacturer of cable gland.

Components from one product can’t be utilized in that of another.

Doing that will impact the safety of cable gland installation and cancel any explosion protection certification.

- Take note that a cable gland isn’t a user-serviceable item.

It’s also under certification protocols.

Spare parts aren’t allowed to be supplied for items which have been put into service already.

- Cable gland sealing rings are added in the cable gland if dispatched from the factory.

You see, there must be no cases where seal rings should be eradicated from the cable gland.

- Care must be taken to prevent exposure of cable gland sealers to:

- hostile chemical substances (like solvents or other foreign bodies)

- dirt

Installation Instruction

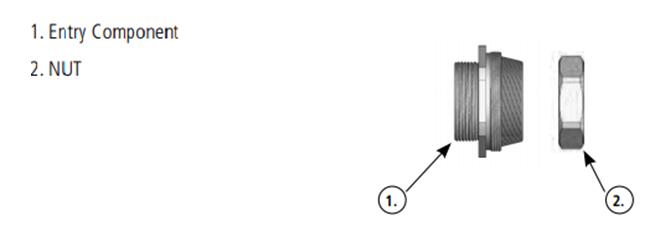

Take note that it is not obligatory that you dismantle the cable gland any further, as illustrated below:

To start the cable gland installation, here’s what you need to do:

- Detached components (1) and (2).

- If needed, fit a shroud over your outer cable

- Manage the cable by eliminating the cable outer sheath and the armor/braid to fit the geometry of the equipment.

- Take away 18 millimeters further of the outer sheath to reveal the armor.

- If applicable, get rid of any wrappings or tapes to show the inner sheath.

TAKE NOTE!! On maximum size cables, the clamping ring might only pass over the armour.

6. Then, secure the entry component into your equipment as shown.

7. Pass your cable through the entry item and space the armor or braid evenly around the cone.

8. While keeping to push the cable forward to prevent contact between the cone and the armor, tighten the nut by hand to engage the armor.

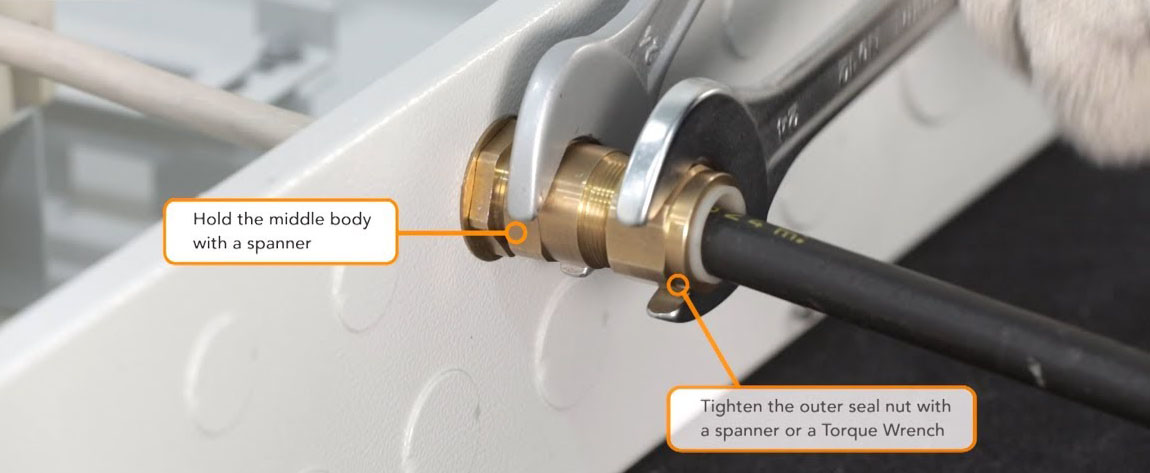

9. Hold the entry component along with a spanner and tighten the nut with the help of a spanner ‘til the armor is secured.

10. The installation is now complete.

If you want to install an IP68 waterproof function cable gland, here’s how you can do it.

You see:

This type of cable gland makes it simple and smooth to run through an enclosure.

You are required to drill a hole of 15.6 millimeters in diameter into the side of your enclosure.

Then you can now screw the two halves of your cable gland into either side of the hole.

Now, the cable runs through, and you rotate the cap to tighten it around your cable.

And you’re done.

Conclusion

Cable glands are made for use with either non-armored or armored cable.

If used with armored cable, they offer ground earth for the cable design.

A compression ring or O-ring sealing element can tighten around the diameter of the cable.

It seals any risky flames, sparks or currents from coming to the machinery to which the cable leads.

They could be made of an array of plastics and metals, depending on their application.

These could be:

- aluminum

- brass

- plastic or

- stainless steel

Because they are made with safety in mind, it’s vital that cable glands bring one or more of the following electrical safety specification ratings.

Some of these are:

- IECx

- ATEX

- CEC

- NEC

- or likewise depending on the nation of origin as well as use

So if you want to get your cable glands, it is crucial that you size them appropriately.

That’s because only one cable can be utilized with one gland.

And the seal should be made with included o-ring.

Not with other elements the user might introduce like tape.

You will find a lot of glands accessible at different manufacturing outlets.

You can look a bit online and create a list of local dealers or manufacturers to receive the best offer.

We hope we presented you with useful information about how cable glands work.

What are your thoughts about this post?

Share your thoughts with us by sending your comments to us!

If you have a question related to how do cable glands do work or if you like to know more, ask in the comments.

You’ll receive the answer from market experts shortly.