Explosion Proof Cable Gland

Explosion-proof cable glands are designed to protect the explosion-proof power cables which applied in a hazardous area with IEC Ex & ATEX certificate, so sometimes it also called Atex cable glands.

Explosion-proof cable glands are designed to protect the explosion-proof power cables which applied in a hazardous area with IEC Ex & ATEX certificate, so sometimes it also called Atex cable glands.

Explosion-proof cable glands made of metal as gland body material such as stainless steel and brass, because the metal material could have a good performance on explosion-proof and corrosion.

Explosion-proof cable glands are widely used in the fields of marine, oil, gas, and other medium and high voltage transmission systems.

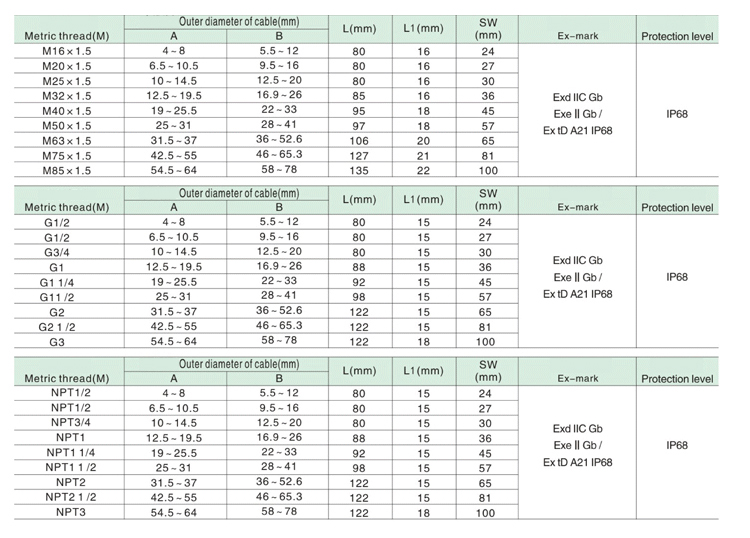

Ex-proof cable gland could be available in any type thread such as PG, metric, and NPT, the sealing protection degree could reach IP68 and 15 bars.

CEO Notes

Hey, Thank you for your interest in our explosion proof cable gland. Our explosion-proof cable gland has certificates such as ATEX certification and IP68 waterproof certificate, which could ensure perfect performance in the hazardous area with class 1 div 1 degree. Please don't hesitate to send an inquiry to us, thanks!

Questions You May Ask About Our Explosion Proof Cable Gland

We have full range sizes of the explosion-proof cable gland ranging from M20 to M100 for metric thread type, G 1/8 to G3 for G thread type.

We produce different types of explosion-proof cable glands, such as single compression explosion proof cable gland, double compression explosion proof cable gland, explosion-proof armoured cable gland etc.

The explosion-proof cable gland is used for fixing the electrical cable to the explosion-proof equipment in the hazardous location, ensure that the wiring of the enclosure which the cable enters can be maintained permanently.

Our company is producing different standards of the explosion-proof cable gland with flameproof function for our customers’ requirements, such as class 1 div 1 cable gland, all of them are atex certified.

We have ATEX certificate especially for explosion-proof type cable gland

Some of the hazardous areas require high protection degree, such as class 1 div 1.

Explosion Proof Cable Gland: Ultimate Buying Guide

Introduction

Introduction

Putting electrical equipment in a hazardous area is a huge deal.

Picking and using the wrong cable gland turns from costly to life-threatening.

Explosion-proof cable gland used in the hazardous area for keeping the electrical cable wiring in the equipment.

You will also find two directives when you are dealing with the explosion-proof cable gland.

These are the IECEX and ATEX.

If you want to know all about the explosion-proof cable gland and its certification, read further.

Chapter 1: Explosion Proof Cable Gland Definition: What is Explosion Proof Cable Gland?

Did you know?

An explosion-proof cable gland is utilized generally in a hazardous area?

Yes, you read that right.

It also has a flameproof function for commercial and industrial applications.

This type of cable gland is developed for strict adherence to global specifications.

They meet North American and international codes and standards including:

- IECEx

- ATEX

- CEC

- NEC and

- other regional certifications

Explosion Proof Cable Gland Functions

The environmental settings in most industry and explosion-proof applications pose a massive challenge for the system components.

Moisture, vibrations, dust, and extreme temperatures affect the installed devices.

Thus, cable glands should be able to endure those stresses as well.

An explosion-proof cable gland functions by making sure it process reliability in those demanding environments.

This type of cable gland is created such that they can be utilized universally in any enclosure series.

What’s more, they are also as simple to utilize in both low and high-temperature settings.

Along with impact resistance, these explosion-proof cable glands provide higher levels of protection against:

- external influences

- impacts, and

- shocks

The best thing about explosion-proof cable glands is its suitability for use in an extended temperature range.

It also provides practical conformity along with current standards.

You see,

Those cable glands guarantee reliable and safe functioning in a wide array of applications.

This hazardous area cable gland offers gas-tight compound protection around the cable.

It features an IP66 environmental seal on the outer cable sheath.

Furthermore;

The gland entry thread protection rating is IP54.

It can be enhanced to IP66 by utilizing an entry thread washer.

Explosion Proof Cable Gland Applications

Some of the industries where an explosion-proof cable gland is a huge help include:

- processes-intensive industries such as

- motor

- machine construction

- energy production

- drive technology

- device components

All of these applications are subjected to high stresses.

An explosion-proof cable gland can endure even the harshest environmental conditions.

In fact:

It’s guaranteed impact-resistance of up seven Joules over a long temperature range.

Other applications of ex-proof cable glands include;

- for hazardous settings

- machine and apparatus engineering

- plant installation

- measuring and control engineering

These cable glands can be utilized in settings of the explosion.

It can endure extreme temperature conditions as well.

What’s more:

They are impact resistant up to seven Joules.

These could be utilized in any enclosures, which ensures versatile capability along with complete standard conformity.

The explosion-proof, heavy-duty and hazardous rated cable gland are also ideal for:

- automated process control

- instrumentation systems

that should run in harsh environments

These cable glands provide a dependable connection in:

- data acquisition

- distribution and transmission

- communication systems

- process control

- embedded computer and other applications where class-rated or zone connectors are needed

Below are some of the zones where explosion-proof cable glands can be utilized:

- Zone 0 Hazardous Area

This is a location in which an explosive setting has a mix of air of flammable substances in the form of:

- mist

- vapor

- gas

for a long period.

- Zone 1 Hazardous Area

This is a place where the explosion setting is composed of a combination of mist, vapor, and gas and tends to happen in normal operation frequently.

- Zone 2 Hazardous Area

Similar to zone 1 and zone 3, this is a place where there’s a combination of flammable substances.

However, it isn’t likely to happen in normal operation.

But, when it does happen, it persists for a limited time only.

Explosion Proof Cable Gland Sizes

You are already aware that explosion-proof cable glands can be utilized in both:

- indoor applications

- outdoor applications

Now, what about its sizes?

These cable glands are available in various sizes.

They are also available in different finishes, shapes, and different designs.

When it comes to sizes:

Bear in mind that every gland size offers a maximum number of cable roes that can be accepted in the gland body.

Some of the gland sizes include:

PG16, PG20, PG25, PG32, PG40, PG50, PG63, PG75

Take note that small, medium, and large are available in different types in a single size.

Ex Cable Gland Selection Chart

Do you utilize a cable gland in compliance along with the IEC 60079-1?

You see,

This has been certified as part of the enclosure.

If so, your cable gland is ideal for use.

If your installation isn’t in compliance with this, use the selection chart to choose the ideal cable gland.

Below is the selection chart for explosion-proof cable gland:

1)

Flameproof sealing devices specified in the equipment documentation with IEC-60079-1 and using a cable gland suitable to the cables utilized.

The sealing device must integrate compound or other suitable seals that allow stopping around individual cores.

The sealing device must be fitted at the entry point of cables to the equipment.

2)

Explosion-proof cable gland specified in the equipment documentation with IEC 60079-1, integrating compound filled seals, which seal around the individual cores.

The word ‘volume’ is determined in IEC 60079-1.

Internal sources of ignition are composed of equipment temperatures and sparks.

These take place in standard operations that can cause an explosion.

Take note:

An enclosure comprising terminals or an indirect enclosure is determined not to institute an internal source of ignition.

Chapter 2: Explosion Proof Cable Gland Parts

What are the different parts of the explosion-proof cable gland?

In this section, we will categorize the different parts of this type of cable gland including:

- cable body

- washer

- nut

- cone ring

- earth tag

Cable Body

The body of the explosion proof cable gland is usually made of metal.

Often, it could be made from steel, stainless or plastic.

That’s because the metal material could offer better performance on corrosion and explosion.

Washer

Can be made of stainless steel, a cable gland washer is fitted internally to the equipment before a locknut.

You see,

It serves as an anti-vibration tool to avoid the explosion-proof cable gland from loosening in service.

Self-loosening must be prevented according to clause 6.4.1 of IEC 60079-14.

That can take place via relative motion over time even with no vibration.

That’s mainly because of the various thermal impacts caused by either variance in:

- clamped materials or

- temperature

Nut

The cable gland nut offers the ideal grip and a tight spanner seal.

These are utilized on cable gland entry threads

Nuts for PG threads sizes are available too.

Ring

A Cone ring is utilized to clamp the cable armor.

It also supports the cable in the gland body armor lock.

Earth Tag

Earth tag is utilized to keep earth conductivity from the cable to junction boxes or external bodies.

Chapter 3: Explosion Proof Cable Gland Installation

Take note that a skilled technician or engineer should do the installation of the ex-proof cable gland.

That’s because failure to comply along with the instruction below will render the IECEx and ATEX certifications invalid.

The client might not modify the cable glands.

Assembly Instruction:

- Operating temperature range from -40 degrees Celsius to +100 degrees Celsius

- Ex-proof cable gland offers a seal on the outer cable sheath and is preferred for use in plastic insulated cables and non-armored elastomer cables

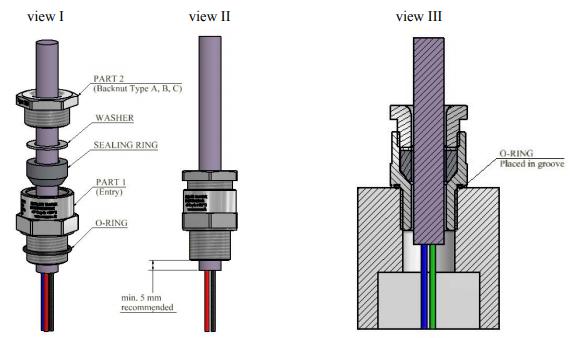

- Pass your cable through the explosion-proof cable gland (check view I)

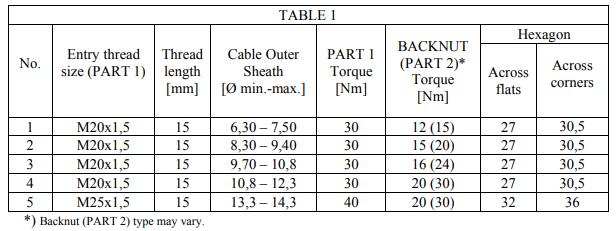

- Tighten the entry into the equipment along with a wrench or spanner with torque presented in Table 1. Here, you need to make sure that the O-ring is positioned in the groove (check view II).

- Hold your cable and tighten it into the entry with a wrench or spanner along with a torque presented in Table 1.

Conclusion

Explosion-proof cable glands command the use of sturdy materials and proactive builds.

These are made to avoid unwanted explosions of flammable substances in hazardous settings.

Compared to your conventional tools from your local electronics or hardware store, these innovative items are made to mitigate the creation of sparks via non-ferrous materials.

We hope we presented you with helpful information about explosion-proof cable glands.

If you are looking for answers about these devices, leave your comments below, and we are glad to help!