Introduction

Are you currently in the market looking for a cable gland types for your individual needs?

If your answer is yes, you are in the right place!

In this ebook, we will guide you about the different types of cable gland as well as their functions.

Generally, a cable gland is a power source for the connection cable.

It safeguards the cable, so it doesn’t escape.

These cable glands are situated in various categories depending on whether the glands are used in:

- general processing industry or

- where the protection is needed to avoid explosion hazards or too much temperatures

A series of cable gowns which fit into the gland and different types of the gland will be needed.

The gland itself could be made of:

- metal

- plastic

- aluminum

- copper

These materials are helpful in various settings.

If the electrical work is finished, it might be without a cable seal to protect the electrical equipment wires.

Nonetheless, for various reasons, that’s a bad idea.

In case you didn’t know yet:

The glands offer sealing power to make sure the cable doesn’t slip throughout the operation.

Safety is also given as the glands guarantee that electrical energy can be connected to cables near anyone, causing injury.

Glands typically offer other safety features like insulated cables or grounding wires.

After reading this ebook, you will understand the different categories of cable glands according to:

- materials

- functions

- shapes

- threads

- compression types

- applications and;

- waterproof degrees

Now, without further ado, do you want to know the different types of cable gland?

Let’s get started.

- Cable Gland Types According to Different Materials

- Cable Gland Types According to Different Functions

- Cable Gland Types According to Different Shapes

- Cable Gland Types According to Different Threads

- Cable Gland Types According to Different Compression types

- Cable Gland Types According to Different Applications

- Cable Gland Types According to Different Waterproof Degrees

Cable Gland Types According to Different Materials

Did you know that material is very crucial specification when choosing a cable gland?

The most typical material types of cable glands accessible are:

• nylon cable gland,

• stainless steel cable gland,

• nickel-plated brass cable gland,

• aluminum cable gland,

• plastic cable gland, and

• PVC cable gland

Take note:

The material must be strong and durable enough to execute for the needed time in the application.

It must also be compatible along with the cable material to avoid:

• damages

• too much wear

• corrosion

Nylon Cable Gland

In case you didn’t know yet, a nylon cable gland can come in various colors such as blue and red.

That simply means you can color code your cables.

When utilized in specific facilities, a color-coded system of cables for your telecommunications or data application would make maintenance job a lot simpler and more efficient.

Nylon cable glands are vital items when we talk about the strain relief of cables.

This electrical cable gland types will be vital in any areas where space is a bit limited.

Such moisture-resistant nylon cable glands could be critical any time even a small amount of moisture that may come in contact with the region of ingress of your cable or wire.

What’s more:

Such cable gland types will also ensure that your wires will be safeguarded from strain and tension.

Stainless Steel Cable Gland

ss stainless steel cable gland

This type of cable gland is one type of metal cable gland along with IP69 and IP68 bar waterproof function.

This cable gland type has remarkable anti-corrosion function against the extreme working setting with:

• alcohol

• gasoline

• weak acids

• saltwater

• etc.

Stainless steel cable gland offers high-grade cable strain relief need and protection from harsh setting.

These cable glands are widely used in industries like:

• communication base stations

• industrial automation

• outdoor lighting and;

• renewable energy

It could enforce the entire system and safeguard the infrastructure from damage.

Thus, it offers strain relief for applications.

Nickel Plated Brass Cable Gland

Meanwhile:

Nickel-plated brass cable gland is a type of cable gland which adopts brass as the raw material

These are widely employed in different applications such as

• machine

• marine

• instrument

Do you plan to use a nickel-plated brass cable gland?

If your answer is yes, then it will offer you a wide clamping range of the cable size.

What’s more:

It will also provide you with excellent anti-corrosion protection.

A brass cable gland is perfect for the harsh setting for heavy machine operating.

Its working temperature could range from -40 degrees Celsius to 120 degrees Celsius.

Aluminum Cable Gland

Aluminum cable glands are appropriate for use with single-core PVC sheathed aluminum wire armored cables for either outdoor or indoor environments.

The gland offers an IP66 environmental to the outer sheath of the cable.

This type of gland offers electrical continuity and mechanical retention through armor wire termination.

Plastic Cable Gland

On the other hand, a plastic cable gland is often utilized as a substitute to metal cable glands.

This type of electrical cable glands offers corrosion-resistant cable entry into electrical equipment.

They secure the wires and cables by offering relief by keeping enclosure sealing requirements.

PVC Cable Gland

PVC is another strong, but lightweight plastic cable glands.

You see, it’s made of softer and is flexible through the addition of plasticizers.

They are appropriate for adding added protection to cable glands, particularly in harsh environments.

Cable Gland Types According to Different Functions

You are already aware that cable glands might be utilized on all kinds of cables including:

- telecommunications

- data

- instrumentation

- control and;

- electrical power

These are utilized as a termination and sealing device to make sure that the attributes of the enclosure that the cable enters can be sustained sufficiently.

In this section, we will guide you on the different types of cable glands according to functions.

Let’s begin:

Waterproof Cable Gland

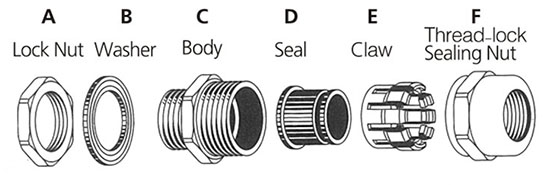

A waterproof cable gland is a device utilized to help in the connection of cables in electrical enclosures.

This type of cable gland helps to keep the watertight seal where the wire enters the enclosure.

This is composed of a nut and a body.

Either the glands could be composed of a separate gasket or cable seal, and those could be incorporated into the cable gland body.

This cable gland type is assembled in a circular cutout within the enclosure.

It captures the wall of the enclosure between the nut and body establishing that watertight seal.

Waterproof cable glands come in a wide array of types, materials, and sizes.

Some of them come in:

- stainless steel

- aluminum

- nylon

- plastic or;

- brass

The material you pick will vary on the particular application.

For example:

To avoid aluminum for outdoor application because it can rust.

Explosion Proof Cable Gland

Explosion proof cable glands are electrical cable gland types that safeguard the exploit-proof power cables.

These are made from brass and stainless steel material.

Metal is a good material as it offers good performance on corrosion and explosion.

Some of the industries where explosion-proof cable glands are used includes:

- gas industries

- oil industries

- marine industries

- other mediums and high voltage transmission system

EMC Cable Gland

An EMC cable gland is short for Electromagnetic Compatibility.

This type of cable gland can operate in its electromagnetic settings without causing any unacceptable electromagnetic obstruction to any device in its environment.

Furthermore:

EMC cable glands can contact the cable shield.

It can compress the cable seals and offer EMC protection through the cables and the equipment.

Typically, EMC cable glands are made by brass and stainless steel materials.

They offer the perfect strain relief function.

They also enable hassle-free and simple installation.

They are utilized in various applications that need to be shielded cables for electromagnetic protection.

This cable gland types pdf help in keeping the electromagnetic integrity of the shielded cable through compressing the gland.

It also offers an IP68 protection level and strain relief to the cable.

Armoured Cable Gland

This type of cable gland is an exclusive type terminating cable glands.

These are made for wire braid cables applied in a hazardous regain along with ATEX Certificates.

You see:

Armored cable glands are typically made of brass material or stainless steel material.

They offer relief for the armored cables.

The metal material could make sure the cable gland along with anti-corrosion function will perform in excellent condition in explosion-proof requirement cases.

Moreover:

The armored cable gland kits could guarantee the waterproof function reaches IP68 grade.

Spiral Flexible Cable Gland

A spiral cable gland serves the purpose of safeguarding a cable from sharp edges in an exit hole cut in a case.

What’s more:

It also offers strain relief to the cable that is practical in projects where the cable will be moved manually or mechanically frequently.

This types of cable glands are resistant to:

- sand

- dirt

- dust

Spiral cable glands offer an optimum strain relief for flex and static applications.

It also features:

- water pressure with a huge clamping range

- strong rubber seals to safeguard against dripping water

- high strength polyamide body compositions

Spiral cable glands are made of nickel.

Its bend design can avoid the cable from overbending repeatedly.

Thus, it lowers the risk of break.

This is ideal for gas stations, charging pile and so on.

Breathable Cable Gland

This instrument cable gland type is made of stainless steel or nickel plated brass.

Breathable cable gland

Some of the features it offers include:

- balance the external and internal pressure

- high-performance gas-permeable membrane design

- the humidity of the equipment to avoid fogging and;

- boos product life

This type of cable gland is mostly utilized in the LED lighting sector.

Cable Gland Types According to Different Shapes

Did you know that cable gland types are also categorized into shapes?

Yes, you read that right.

In this section, it’s time for you to uncover the different shapes of a cable gland.

Straight Cable Gland

As what the name implies, a straight cable gland features a conventional shape.

These are perfect for fixing the ends of flexible corrugated conduits to the cable entries on the terminal boxes on an electric motor, control panels and more.

90 Degree Cable Gland

On the other hand, this type of cable gland protects cable elbows every time extracting the cable in a right angle direction.

It has an IP68 protective structure compliant.

It also supports wider cable diameter ranges compared to a separate model.

Cable Gland Types According to Different Threads

So far, we have already uncovered the different types of cable glands according to:

- materials

- functions, and

- shapes

Now, we are now categorizing cable gland types according to threads.

There are at least four types of thread standards utilized.

PG Thread Cable Gland

This thread is utilized to combine pieces of cable glands and electrical conduit.

According to Wikipedia, it’s a technical term made in Germany and often utilized in different countries.

Metric Thread Cable Gland

On the other hand;

The ISO metric screw threads are the most commonly utilized type of screw thread.

They were considered one of the first international standards approved when the ISO was founded in 1947.

You see:

The letter “M” designation for metric screws tells the nominal outer diameter of the screw in millimeters.

NPT Thread Cable Gland

The National Standard Pipe Thread standards also known as NPY is a national technical standard for screw threads utilized on pipe fittings and thread pipes.

They are composed of both straight thread series and tapered series for different purposes such as:

- pressure tight sealing,

- rigidity, or

- both

G Thread Cable Gland

Lastly, G Thread is part of the BSP technical standards for screw threads, which have been adopted globally.

They interconnect and seal fittings and pipes by mating an internal female thread and external male thread.

These parallel threads are having constant diameter denoted by the letter G.

Cable Gland Types According to Different Compression Types

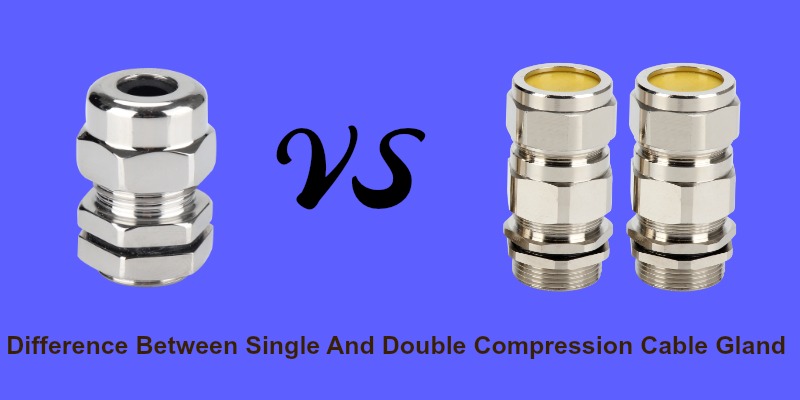

You are already aware of the different types of compression cable glands.

They are:

- single compression cable gland and;

- double compression cable glands

However, what is the differences between the two?

In this portion, we will some of their major differences and functions too.

Single Compression Cable Gland

A single compression cable gland is a cable gland type that can be employed in an average climatic environment.

These are protected by PVC shrouds and can be used in extreme environments.

One of the features of this type of cable gland is that they are available in different sizes.

What’s more, they are suitable for all kinds of cables at least 1,000 sq.mm.

They also control at least 61 cores.

This compression cable gland helps in providing electrical continuity among:

- unarmored cable

- gland entry component

It also features a seal on the outer sheath of the cable.

Thus, it guarantees no damage is presented to the cable sheathing.

These swa cable gland types are employed both in outdoor and indoor applications.

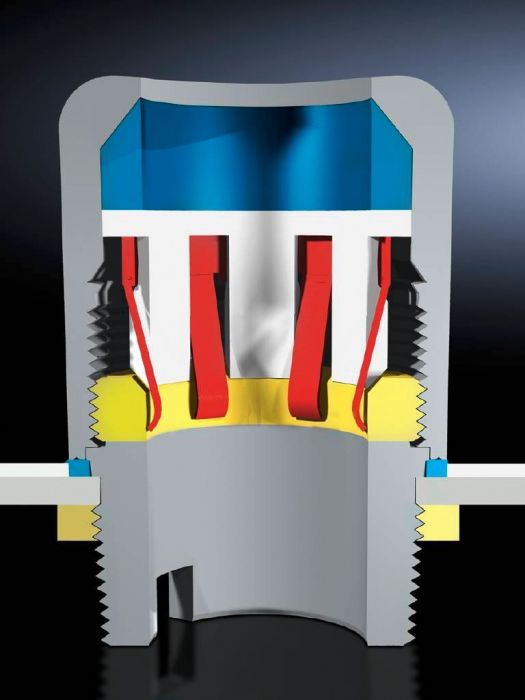

Double Compression Cable Glands

Now, what about double compression cable glands?

What makes it different from single compression cable gland?

You see:

This kind of compression cable gland is used where big armored wires are getting or entering into the board.

This cable gland types offers added support and boasts a double sealing feature.

You will find a compression at the cable armor and inner sheath.

Also:

If you are looking for weatherproof or flameproof cable glands, this cable gland type got you covered.

Cable Gland Types According to Different Applications

Typical applications for cable glands include:

- instrumentation

- electrical

- marine

- motor and;

- industrial

Instruments Cable Gland

Designing and testing of electrical equipment need high-quality cable connectors.

This is to guarantee accurate, repeatable connections as well as data protection.

Instruments cable glands can be utilized from seabed refineries to any space modules.

Often, they are modified for hazardous settings with appreciable NEMA and IP ratings.

This cable gland types are utilized along with conduit or communications cable.

Electrical Cable Gland

Meanwhile:

Electrical cable glands can be employed with a wide array of cable types.

This includes unarmored and armoured cable glands.

They are also accessible in stainless steel, nickel plated brass and brass materials.

They are designed and rated specifically for penetration into electromechanical assembly enclosures or electrical panels.

Marine Cable Gland

Marine cable glands are types of cable gland created for applications on:

- drilling settings

- offshore mining or;

- other marine applications

Motor Cable Gland

This type of cable gland is designed for use in motors and associated installations.

Industrial Cable Gland

Did you know that an industrial cable gland is a cable gland type that meets the general hazard requirements?

Thus, it is very practical for use for:

- explosion hazards or

- high-temperature environments

When the environment is hazardous, you can use dangerous glands.

But why?

That’s because they meet the necessary added requirement.

Aside from that:

They have added reinforcements, which make them resistant to external forces or temperatures, which the glands cannot endure.

What’s more:

This device is made for connecting and protecting the ends of a cable to a piece of equipment.

It offers strain relief and links by a means appropriate for a particular type and description of cable for which it was made.

That consist of the provision for creating electrical connections to the braid or armor or the aluminum sheath of the cable.

This type of cable gland can also be utilized for sealing cables, which pass through gland plates or bulkheads.

Such type of cable glands can also be utilized on the majority types of:

- telecommunications cable

- instrumentation cable

- data cable

- control cable and;

- electrical power cable

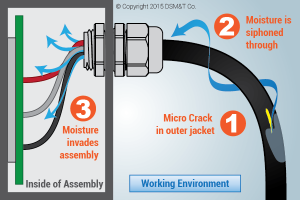

Cable Gland Types According to Different Waterproof Degrees

IP Rating also called as Ingress Protection.

They are utilized to determine the levels of sealing effectiveness of electrical cable gland against invasion from foreign bodies like moisture and dirt.

Now, every number connected to the IP rating tells the level of protection.

For instance:

The number 6 in IP68 denotes intrusion protection.

On the flip side

The 0 means no special protection.

The number 3 denotes protection from entry by tools with a diameter of 2.5 millimeters or more

The number 6 denotes it’s totally dust tight.

Aside from that:

The second number, for example,

The number 8 in IP68 tells the degree of protection from various types of moisture.

The 1 means protection from condensation.

The number 5 denotes protection from low-pressure water jets.

The number 8 simply means that it’s safeguarded prolonged effects of immersion under pressure.

If you want to know more about the IP rating of cable gland, read further:

IP66 Cable Gland

In case you didn’t know yet:

Using weatherproof cable glands is an efficient and simple way to safeguarding against moisture coming your:

- project box

- junction box or

- enclosure

Choosing a proper cable gland connector rated for IP66 is an excellent way to safeguard your important components inside of your project box or enclosure.

IP67 Cable Gland

This type of cable glands is very sought-after.

It’s the primary type of waterproof connector within the market.

IP67 series of cable glands are of top quality.

They also have a high waterproof grade.

It offers long-term durability under harsh climatic conditions.

What’s more:

The IP67 rating simply means that your cable glands are safeguarded from dust.

It’s also capable of enduring water immersion between fifteen centimeters and one meter for 30 minutes.

IP68 Cable Gland

IP68 cable glands are cable gland types that are regarded as the highest waterproof cable gland.

Based on these waterproof sealing performance criteria, IP68 cable glands denotes it can stop dust from entering completely.

It can constantly under pressure immersed in.

You see:

IP68 waterproof cable glands are made for demanding setting dust tight and constant immersion.

IP69 Cable Gland

The IP69 rating offers protection rating against:

- high-pressure water

- ingress of dust

- high temperature

That makes cable glands with this certification perfect for use in conditions where the equipment should be sanitized carefully.

Cable glands that are IP69 are suitable for the wire binding, compression, and passage between two compartments such as:

- junction boxes

- devices needing sealing

Conclusion

Cable fittings, cable connectors, or cable glands might appear like a small thing to think about.

However, it’s the small things, which provide the most sensible and suitable solutions.

When we talk about your cabling needs, be it electrical cables or data cables – DO NOT FORGET CABLE GLANDS.

What are your thoughts about this blog?

Do you have more questions in mind?

Feel free to share your thoughts and inquiries with us by leaving your comments below.

We love to hear about your thoughts!