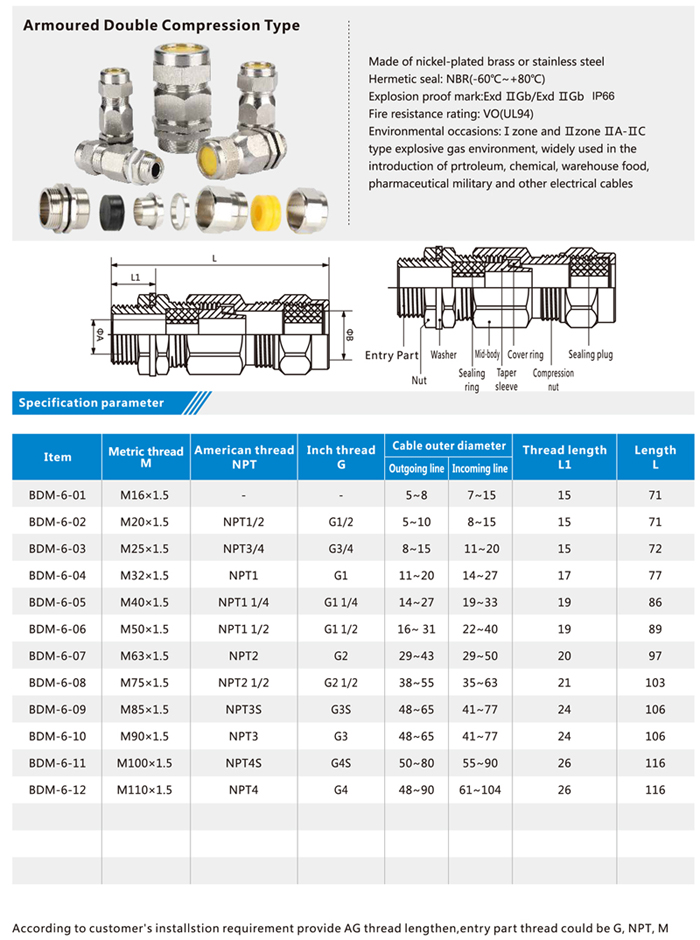

Double Compression Cable Gland

The double compression cable gland, also named the double seal cable gland, is normally designed for all armoured and unarmoured cables to provide compression for both the cable armoured and inner sheath. It provides strain relief and electrical continuity for the electrical cables throughout. It meets the IEC 62444:2010 standard and ensures the protection of the electrical cables in hazardous areas.

Double compression cable glands could be used in corrosive conditions with weatherproof functions outdoors, the high-quality cable gland parts ensure the characteristics of weatherproof protection, fireproof performance, high-temperature resistance, dust resistance, flameproof and waterproof protection etc.

The double compression cable gland is easily loosened from the cable for maintenance because of the detachable armoured parts and clamping ring, the ideal design clamping range ensures double compression cable gland can watch the full range of cable sizes.

Double compression cable glands material are normally made of metal such as SS stainless steel and brass, it is available on metric, PG and NPT thread with IP66 sealing protection degree, and the working temperature could be -40℃ to +120℃.

Double compression cable gland size ranges from 3/8″(10mm) to 4″(100mm) and is suitable for different sizes of cables up to 1000 sq. mm and control cables up to 61 cores.

CEO Notes

Thanks for visiting our website, it's the right place for purchasing double compression IP66 cable gland here. The double compression cable gland is the main product in our business, we could design any types as you need. Please send me your detailed specifications soon. Thanks!

Questions You May Ask About Our Double Compression Cable Gland

As we know, the single compression cable gland is widely used in applications. However, the double compression cable gland can provide a better-fixed function for the installation of the entry cable.

Some special applications must need double compression cable glands such as hazardous areas that need weatherproof function and some armoured electrical cables.

We have the datasheet for our double compression cable gland, that showing the detailed clamping range for the electrical diameter size, you could ask us to get it, then you will find the correct size.

Depends on the different applications of the cable gland, single compression cable gland normally used for waterproof applications and only for unarmoured cables. Double compression cable gland used for some flameproof applications and armoured cables.

Yes, Our double compression cable gland could be applied for armoured cables.

Any thread type as you need, we could make it for you.

We have the metric thread type, G thread type( from G1/2 to G4 sizes), PG thread type etc.

Double cable glands used with all types of armoured & un-armoured electrical cables, providing an environmental seal for the inner & outer sheath of cables.

Normally the application circumstances are hazardous areas with high explosion-proof grades. The double compression cable gland has high-grade function against explosion-proof, which could ensure the sealing cables work in proper condition always.

The double compression cable glands are used for passing, holding, and compressing cables between two compartments such as distribution box, switchgear or some other devices that need sealing against oil and gas.

The HS code of the double compression cable gland is the same as the normal waterproof cable gland, it’s 8547901000

Our double compression cable gland main body made of the metallic material, such as nickel-plated brass or stainless steel.

Double Compression Cable Gland: Ultimate Guide for Importers

Are you one of those people seeking information about the double compression cable gland?

You see:

A double compression cable gland has a waterproof rating of IP66.

Devices that are backed by a standard rating of IP66 are considered fit enough to endure:

- Sand

- dirt,

- and dust.

They are also resistant to submersion up to a maximum depth of 1.5 meter underwater for at least 30 minutes.

Meanwhile:

IP66 is dust-tight and safeguarded against powerful jets of water and heavy seas.

It is used for:

- passing

- holding and;

- compressing

cables between the two compartments.

This compartment might be:

- electrical boxes

- junction boxes

- cabinets or;

- devices needing sealing against gas or dust.

In this e-book, allow us to present you the information you need to know about double compression cable glands.

Do you think you have what it takes to digest all the specifications we will present?

If you answer is yes, let’s begin!

Chapter 1: Double Compression Cable Gland Definition: What is a Double Compression Cable Gland?

What is meant by double compression cable gland?

Did you know?

As the name suggests, double compression glands occur at the cable armor and the inner sheath.

This is sort of two sealings, thus called “double.”

Therefore, changes in vapor and moisture entry are lowered.

That’s the reason why these types of cable glands are also called:

- flameproof cable glands and

- weatherproof cable glands

A double compression cable gland is much known as a fitting or cable connector.

This is a device that is made to connect and secure the end of a cable to the equipment.

You see:

A double compression cable gland offers strain relief.

It links by a means appropriate for the kind and description of cable for which it is made.

This includes provision for establishing electrical connection to the braid or armor and aluminum or sheath of the cable.

A double compression cable gland is a mechanical cable entry devices.

It can be manufactured from:

- metallic or:

- non-metallic materials

These cable glands are employed throughout a series of industries in conjunction along with wiring and cable utilized in:

- automation and;

- instrumentation systems

Double compression cable gland in the distribution box

Also:

Double compression cable glands might be utilized on all types of:

- data & telecommunications cables

- instrumentation

- control and;

- electrical power

They are used as a termination and sealing device.

That is to guarantee that the features of the enclosure, which the cable enters, could be kept sufficiently.

When we talk about double compression cable gland, here’s what you need to understand:

A double compression cable gland is typically made for all unarmoured and armoured cables.

Its function is to offer compression for both on the inner sheath and cable armoured.

It also offers electrical continuity and strain relief for the electrical cables within.

In case you didn’t know yet:

Double compression cable gland could also be employed in the corrosive condition.

You can use a weatherproof double compression cable gland outdoors too.

You see:

The top-quality cable gland parts guarantee the features in:

- waterproof protection

- flameproof

- dust resistance

- high-temperature resistance

- fireproof performance

The double compression cable gland is loosened easily from the cable for maintenance.

That’s because of the detachable armoured parts and clamping ring.

The suitable design clamping range guarantees a double compression cable gland can see the overall range of double compression cable gland size.

Brass material double compression cable gland

Typically:

Double compression cable gland materials are made by metals like:

- brass and;

- stainless steel

It is accessible on:

- metric

- NPT and

- PG thread

It has an IP68 sealing protection level.

Its working temperature could be -40 degrees Celsius to +120 degrees Celsius.

Double compression cable glands offer added support to the heavy armoured cables that enter and exits in the panel.

Through this cable gland, the compression takes place both at the inner cover and cable shell.

Therefore, it lowers the moisture vapor in it.

These cable glands are considered:

- weatherproof

- flameproof and;

- dustproof

These cable glands are widely utilized in:

- gas sector

- oil sector and;

- more industry as per its requirements

Types of Double Compression Cable Gland

Did you know that there are various types of double compression cable glands as well?

Yes, you read that right!

Below are the different types of double compression cable glands and their functions:

- Double Compression Weather Proof Cable Gland

- Double Compression Flame Proof Cable Gland

- Double Compression Medium Duty Cable Gland

- Double Compression Dust Proof Cable Gland

Chapter 2: Double Compression Cable Gland Parts

What are the parts of a double compression cable gland?

In this section, we will list the different components of a double compression cable gland and their functions.

Check Nut

Cable glands are composed of 3 different parts.

Two gland halves and a split sealing grommet.

These are screwed together along with the hexagonal cable gland nut.

You can pick from a wide array of materials and sizes including:

- fiberglass – for use with plastic round top thread cable glands

- stainless steel – corrosion resistant along with improved strength at high temperatures

- brass – suggested in securing bras cable glands and accessories into equipment or to a gland plate

Entry Seal Ring

An entry seal ring is utilized to combine two parts of an engine, machine or other mechanical assemblies.

It fills the space among both parts, making a seal and filled space in the idle.

That seal stops fluid, vapor and particle leakage to safeguard and keep pressure while keeping debris out.

It also guarantees proper safety and function.

An entry seal ring is utilized in different fields and industries such as:

- general engineering

- aerospace

- automotive

This is generally made of rubber.

It is position inside the body of the cable gland to serve as a seal.

You see, entry seal ring offers safe and secure coverage for the entry point of the cord and the cable.

Nipple Entry Part

Inner Seal Ring

An inner seal ring with various holes is utilized in place of the inner sealing insert.

The sealing insert allows various cables to be fed at the same time through the single gland.

Thus, components could be dimensioned smaller, as there’s no need to utilize one separate gland per cable.

Armour Clamping Cone

Clamping cone allows clamping of the square and round pipes by simply positioning them.

You see, a clamping cone is attached with bolts.

Armour Clamping Ring

Main Gland Body

The cable gland’s body, as well as housing, are generally made out of:

- plastic

- steel

- stainless

- steel

- aluminum

The housing and the body are composed of all other components of the cable gland.

Outer Seal Ring

The outer seal ring is much the same to a seal.

It’s seated in a groove in one of the 2 parts to be combined then compressed among such 2 components to the corresponding groove.

You see, it builds a securely sealed joint.

They can be utilized in dynamic joints where there’s movement and in fixed or static applications.

In case you didn’t know yet, outer seal rings come in different materials fitted to various purposes.

A few have a high-temperature tolerance for use in both cold and hot settings.

Some are designed to be chemically resistant for use in test or lab equipment.

They are accessible in a wide array of sizes both in single size packs and an outer seal ring kits for general maintenance.

They are also available if you are seeking a variety of sealed part to guarantee the proper size is accessible.

Typically, outer seal rings are made of elastomers such as silicone and rubber.

However, they come in plastics as well, metals and some other materials.

That array of material enables a particular outer seal ring to be utilized to guarantee the most reliable and best fitting seal.

Sizes differ between ring and seal types between both ring and seal types in both thickness and diameter.

Such variations help offer a precise seal to safeguard the joint.

Both imperial and metric sizes are accessible to change old and new seals.

Compression Nut

Compression nut, on the other hand, is small, hexagonal devices.

They are utilized to securing into position each type of cable glands and cable grommets.

You see:

This cable gland parts are utilized in a wide array of industries which employ wiring and cable utilized in:

- automation and;

- electrical instrumentation systems

Cable gland compression nut might be consumed on each type of data & telecommunications cable, instrumentation, control, and electrical power.

Chapter 3: Double Compression Cable Gland Applications: Where Double Compression Cable Gland is Used

Do you currently work in a complex environment of the petrochemical and oil industries?

In hazardous regions, the setting can include:

- vapors

- dust or

- explosive gases

These perilous cases need products that are made to be both:

- explosion proof and;

- flameproof

You see:

Hazardous environments are categorized into various zones.

This is to tell the level of risk and guarantee that the proper apparatus is utilized.

For instance:

In Zone 1, an explosive gas atmosphere tends to take place in normal operation.

On the other side

In Zone 2, it’s not likely to happen.

When it does, it will simply exist for a very short time.

That is where double compression cable glands can be of good use.

No matter if, it is data cables from cable protection on a power transmission unit or a gas detector:

A double compression cable gland is made and produced to meet the standards of arduous and rigorous operating settings apart from IECEx and ATEX standards.

Hazardous area

Environmental Conditions

Double compression cable glands should safeguard the equipment against any environmental impacts.

These impacts are the ones which could intrude through the cable entries.

The standard minimum ingress protection these days is IP68 or IP66.

In the past, rubber shrouds were utilized as an alternative to safeguard metal glands from modern from:

- corrosion and;

- moisture

Nonetheless, those shrouds aren’t suggested anymore.

That’s because latest metal cable glands are extremely corrosion-resistant already.

Furthermore:

The collection of moisture and water between the gland and shroud displays larger stress.

Hazardous area cable glands usually have a massive ambient temperature range.

On the other hand:

Plastic glands are normally appropriate for -40 to +60 degrees Celsius.

The metal cable glands are rated for -60 to +80 degrees Celsius.

What’s more:

Special cable glands for temperatures that have +200 degrees Celsius or above or for lower temperatures are now accessible in the market.

Chapter 4: Double Compression Cable Gland Installation: How to Fix Double Compression Cable Gland

The proper selection of double compression cable glands is vital for the integrity of the explosion protection.

The glands need to match the cables which are utilized and the form of protection used for the equipment at the location of installation.

What’s more:

Direct entry into flameproof Ex d enclosures through Ex d cable glands is still a known installation method.

However, the proper selection and installation of armoured or barrier cable glands could test the user.

You see:

Double compression cable glands are the most typical means of leading cables into hazardous region equipment.

You will find various factors to be considered when choosing the right cable glands for a particular application.

Generally, there are 3 kinds of cable gland that exist:

- Cable glands made of metal for use with armoured cables

- Cable glands made of metal for use with shielded cables

- Cable glands made of metal or plastic for use with non-armored cables

A few vital criteria should be considered when choosing glands for armoured cables.

For instance:

- the type of armour

- the outside and inside diameter

- spanner size

- and thread size

The gaskets at the enclosure play a vital role when it comes to IP protection.

A dissimilarity should be done here between glands that are screwed into threaded holes.

That’s where the IP protection is ensured by a standard O-ring, as well as installation in through-holes along with lock nuts.

In the following case, a flat gasket is needed to recompense for the through-hole tolerances.

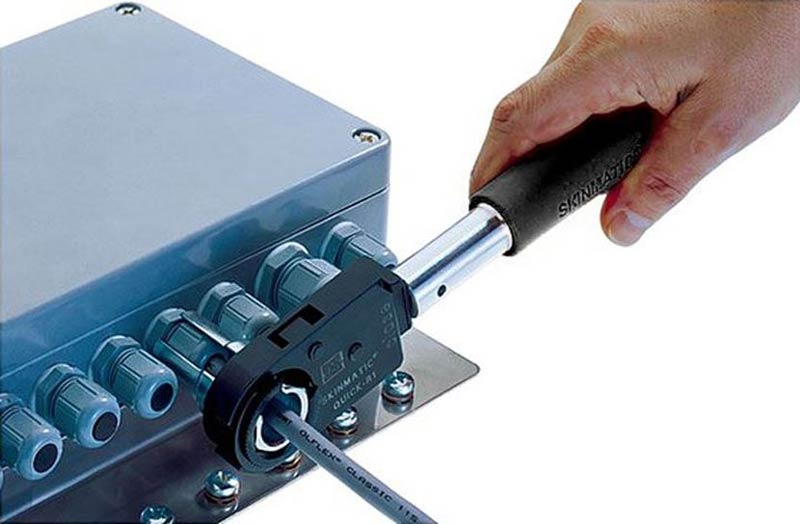

Fix double compression cable gland

Double Compression Cable Glands Installation Considerations

Correct installation is the key to a safe application.

This is where Murphy’s law will apply: anything that could go wrong will go wrong.

You see:

The simpler your gland design, the less the mistakes which could be done on the site.

Ex d cable glands for those armoured cables are composed of at least ten different parts are a great example.

They have to be joined in precisely the proper sequence and fashion.

Following are the crucial things you need to take into consideration:

- proper cutting of the armour

- exact positioning at the end of the armor cone

- appropriate fixing of the armor with the exact tightening ring

One easy but typical issue is the loss of vital internal components when disassembling the armoured glass before installation.

The tightening ring and armour cone are particularly vulnerable in this case.

Quality glands lock the two components together with inner O-rings.

The prevention of water ingress is an added advantage.

Using the proper tightening torques at every step of the installation process is of utmost importance.

Even though in practice, most installers are more likely to depend on their know-how instead of a torque spanner.

Cable glands are among the most vital components for guaranteeing the safe installation of electrical equipment in hazardous environments.

Everybody understands how it works in principle.

However, an entire series of mistakes could be done throughout the selection and installation stage.

That can danger or even ruin the reliability of the explosion protection.

https://youtu.be/JZAmxXJ6fcg

Therefore, to prevent any incident, it’s essential you know the proper installation process.

Below are the steps you need to do:

1. Prepare your cable by getting rid of the cable outer sheath as well as the armour.

This is to fit the geometry of the equipment.

Get rid of the extra 18 millimeters of the outer sheath to show the armour.

2. Split the gland into 2 sub-assemblies: A and B.

That will guarantee that the gland outer body is undisturbed.

Pass the sub-assembly B over the cable outer sheath and armour trailed by the cone ring.

3. Make sure that the inner seal is comfortable by slackening the cone body.

You also need to secure the sub-assembly A into the enclosure.

It can be either through screwing the gland main body into a threaded hole or:

Through securing it in a clearance hole via a locknut as applicable.

4. Find the detachable armour cone into its recess in the cone body.

Then, pass the cable through the sub-assembly B ‘till the armour engaged along with the cone.

Spread the armour consistently around your cone.

5. While keeping to push the cable forward to keep contact between the cone and the armor, why do you need to do?

The next step is to tighten your gland main body via hand until heavy resistance is experienced.

That’s the time when the inner seal makes connect along with the inner cable inner sheath.

You need to tighten this a bit further on a full turn with a spanner.

6. Hold the main body with a spanner.

Tighten the sub-assembly A into sub-assembly B with the help of a spanner.

You need to do this until all accessible threads are utilized.

Ultimately, you need to tighten the gland outer

Perform this until it comes to an efficient stop.

That will only take place when:

- The gland outer body is metal to metal along with the gland inner body

- The gland outer body has involved the cable clearly and can’t be tightened further without the help of too much force by the installer

Chapter 5: How to Select Suitable Size Double Compression Cable Gland?

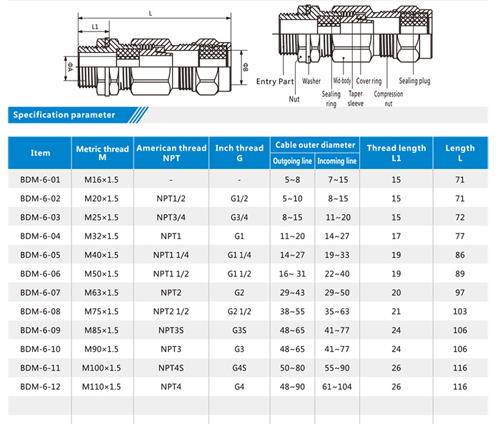

As we know, the double compression cable glands have different sizes and threads types for the armoured and unarmoured cable, the outgoing and incoming cable diameter sizes are also different, so we must have a size selection chart to help us to find the suitable glands.

This above selection chart is very useful for your checking, it including different thread types and sizes, with different cable outer diameter ranges.

Please learn it and contact us if you have any other questions.

Conclusion

To sum up, you now realize that double compression cable glands help in offering electrical continuity between gland entry component and unarmoured cable.

It offers a seal on the outer sheath of your cable.

Thus, it guarantees no damage to cable sheathing.

Such are utilized both in outdoor and indoor applications and in all climatic environments.

That’s mainly because these are waterproof, weatherproof, dustproof and fireproof.

We hope we provide you the necessary information you need to know about double compression cable glands.

What are your thoughts about this post?

Share it with us by leaving your comments below!