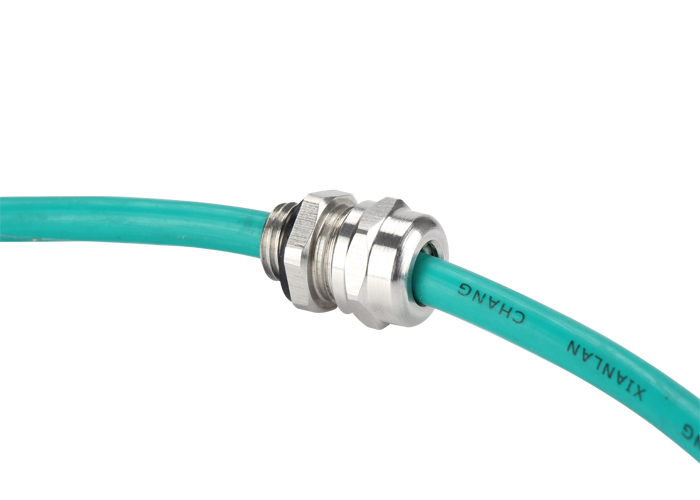

SS Stainless Steel cable gland

Ss stainless steel cable gland is one type of metallic cable gland with IP68 and IP69K up to 10bar waterproof function, high temp withstanding could up to 150℃. The size of the ss cable gland is ranging from M8 to M100, it is normally used in hazardous areas because of the superior explosion-proof and corrosion resistance performance.

SS stainless steel cable glands also used widely in modular entry systems, beverage industry, food manufacturing industry, etc.

Ss stainless steel cable gland provides high-grade cable strain relief needs and protection against harsh environmental influence. Stainless steel cable glands applied widely in industries range such as renewable energy, industrial automation, outdoor lighting, and communication base stations. It could enforce the whole system and protect the infrastructure from damage, providing strain relief for applications.

Harsh wash downs, microbes, and bacteria will be resisted to ensure your production line working in a normal state, so the Food & Beverage industry adopts so stainless steel material cable gland as SS304, SS316, and SS316L.

SS stainless steel cable gland made of stainless steel 304 and 316L material, because of their anti-corrosion property is especially stronger than other types of metal, such as brass cable gland, so ss stainless steel cable gland applied as marine waterproof cable gland.

Ss Stainless steel cable gland has all kinds of thread types such as Metric, PG, NPT, and is available with short and long thread entry. Our ss stainless steel cable gland is very cost-effective and also perform in reliability, durability, and performance.

CEO Notes

Thank you for your interest in our ss stainless steel cable gland. Our stainless steel cable glands greatly reduce the damage of pollution and deterioration and applied widely in the area with a high level of hygienic requirement. Please tell me any requirement for your project, we will provide you with competitive stainless steel cable glands price list.

Questions You May Ask About Our Stainless Steel Cable Gland

Because the stainless steel cable gland production process is much longer than the brass cable gland, so the producing speed is slow, and the cutting knife costly damaged during the production process.

Brass cable gland scrap value is high, but stainless steel scrap is in very low value.

It is practically impossible to see the difference between ss304 and ss316 stainless steel cable glands with the naked eye. Many people are confused when they see these numbers. Today, come with me to see the difference between stainless steel ss304 and ss316:

SS316 stainless steel contains Mo, which is more resistant to corrosion in high-temperature environments than 304 stainless steel. Therefore, engineers generally choose 316 material cable glands in high-temperature environments.

SS316 has mainly reduced the Cr content, increase the Ni content and increase Mo2%~3%. Therefore, its corrosion resistance is stronger than that of ss304, and it is suitable for use in chemical, seawater, and other environments.

Similarly, the cost of ss316 cable glands is also higher than that of ss304 cable glands. Generally, ss316 cable glands are used in places with higher requirements to replace ss304 cable glands.

The stainless steel cable gland hs code is 7326901900 in the Chinese custom system.

We could produce all thread types for our stainless steel cable glands, such as metric thread, PG thread, and NPT thread.

We have the stainless steel material grades as SS201, SS304, SS316, and SS316L, just according our customers’ requirement.

Yes, we accept any customized drawings as our customers’ provided.

We can make any thread type for the stainless steel cable gland, such as PG, Metric, NPT etc.

No, we could make any type of cable gland in stainless steel material, such as armoured cable gland, double compression cable gland, explosion-proof cable gland etc.

Stainless Steel Cable Gland: Ultimate Buying Guide

SS Stainless Steel Cable Gland

Introduction

In the food and beverage industries or whatever industries you work with, you wish to ensure that your products prevent contamination at every cost.

Dirty equipment and microorganisms can result in unwelcome impurities that can harm the health of your business and your consumers.

Luckily:

Stainless steel cable gland is the perfect material for most applications.

That’s because they are non-corrosive, waterproof, easy-to-clean, and lack pores where microorganisms can flourish and reproduce.

In this e-book, we will provide you with the necessary information you need to know about:

Chapter 1: Different Material Types of Stainless Steel Cable Gland

Before we proceed to the different material types of stainless steel, allow us to define what is stainless steel.

But, what is stainless steel?

In case you didn’t know yet, stainless steel is considered low-carbon steel.

You see:

It has chromium.

It’s that addition of chromium that offers plain steel its distinctive corrosion, waterproof, and stain-resisting properties.

Further:

The chromium in the steel enables the formation of the invisible, rough, corrosion-resisting chromium oxide film on the surface of the site.

When the material is ruined of chromium or other elements like:

- nitrogen

- nickel;

- molybdenum

the steel takes on raised corrosion resistance and some other properties.

Material Types of Stainless Steel

You are aware that there are various types of stainless steel.

All of them has distinct composition and qualities.

And depending on the chemical composition of the steel itself, it might be easier, stronger, challenging to work with, magnetic or not.

Various types of steel have multiple stainless steel cable gland price points, too.

Stainless Steel Rod

1. Type 201 Stainless Steel

Type 201 Stainless steel is known to be an austenitic chromium-nickel manganese stainless steel.

That means it was created to conserve nickel.

You see:

Type 201 is an affordable alternative to traditional Cr-Ni stainless steel like 304 and 301.

That’s because there’s nickel substitution by additions of nitrogen and manganese.

What’s more, it’s non-hardenable through thermal treatment.

However, it might be cold worked to high tensile strengths.

SS201 is also nonmagnetic in the annealed state.

It becomes magnetic if cold worked.

Type 201 stainless steel is replaceable for Type 301 in the majority of applications.

2. Type 304 Stainless Steel

Now, apart from SS201, you also need to know about Type 304 Stainless Steel.

Let’s dive in.

Type 304 is the most widely utilized austenitic stainless steel.

It was sought-after as the 18-8 stainless steel due to its composition

But why?

That’s because it is composed of 8% nickel and 17% chromium.

The SS304 has generous forming as well as welding properties.

It also features high strength, waterproof, and corrosion resistance.

It has very excellent drivability too.

And another thing:

It can be formed into a different shape.

Compared to Type 302 Stainless Steel, utilization is possible with no annealing.

Some of the typical uses for Type 304 stainless steel are evident within the food sector.

Did you know that it is perfect for:

- winemaking

- milk processing

- brewing

- storage tanks

- fermentation vats

- yeast pans and;

- pipelines

Type 304-grade stainless steel can also be seen in

- stoves

- refrigerators

- coffee pots

- tabletops

- sinks

- different utensils and;

- other cooking appliances

It can endure corrosion which can be caused by various chemicals seen in milk, meats, and fruits.

What’s more:

Other areas of applications include:

- screws

- bolts

- marine nuts

- mining equipment

- heat exchangers

- chemical containers and;

- architecture

Type 304 stainless steel is utilized in water filtration systems, mining as well as dyeing industry.

3. Type 316 Stainless Steel

This is the last type of material stainless steel we will discuss.

The Type 316 stainless steel is an austenitic chromium-nickel stainless steel.

This type of stainless steel has 2 percent to 3 percent molybdenum.

You see:

The molybdenum content:

- improves resistance to pitting in chloride ion solutions

- boosts corrosion resistance

- waterproof

- increases strength at extreme temperatures

In other words, it’s especially useful in acidic settings.

It’s also protective from corrosion caused by the:

- tartaric acids

- sulfuric acids

- hydrochloric acids

- formic acids and even;

- alkaline chlorides

- acid sulfates

You need to be aware that type 316 stainless steel is very durable.

But wait, there’s more!

It also features the following benefits:

- easy to fabricate

- clean, weld, and finish

- waterproof

It is substantially more resistant to solutions of:

- fatty acids

- iodides

- sulfuric acids

- chlorides and;

- bromides

at high temperatures.

Beyond that, stainless steel that has the element of molybdenum is even required in the development of exact pharmaceuticals.

That is to avoid too much metallic contamination.

What about the common uses of 316-grade stainless steel?

The most typical uses of SS316 are in the following:

- chemical processing equipment

- evaporators

- jet engine parts

- heat exchangers

- furnace parts

- construction of exhaust manifolds

- photographic and pharmaceutical equipment

- pump and valve parts

- tanks

- pulp, paper, and textile processing equipment as well as;

- components which are susceptible to marine settings

Chapter 2: Nickel-Plated Brass VS. Stainless Steel Cable Gland: Why Should Use Stainless Steel Cable Gland?

In this next chapter, we will tackle the pros and cons of nickel-plated brass vs stainless steel cable gland.

Later on, you’ll understand why it’s better to opt for the stainless steel cable gland.

Are you now ready?

Let’s jump in!

The two most sought-after metallic materials for cable glands are stainless steel and nickel-plated brass.

However, the question is:

Which is the best to use?

What is a Nickel-plated Brass?

Nickel-plated brass is a kind of brass that has a coating of nickel on the surface.

You see, that surface was completed through electroplating.

Its core is pure brass.

Nickel Plated Brass Cable Gland

Commonly, brass provides substantial benefits when compared to stainless steel.

It’s widely preferred for the majority of agricultural and industrial applications.

However, you will find some cases in which stainless steel might be needed.

For instance, stainless steel and nickel-plated brass both feature corrosion-resistant properties.

However, they both respond differently to many corrosive agents.

Take a look at some of the pros and cons of every material.

First is nickel-plated brass cable glands:

- Can be nickel-plated to lessen corrosion and tarnishing or only to offer a silver finish.

The great thing about nickel finishes cable glands is that they present a hard wear surface on items like:

- plumbing

- bearings;

- gears fixtures

- Nickel-plated offers generous strength.

It overlays the tensile strength of 12L14 low-carbon steel.

If designers should develop a threaded portion stronger, an easy boost in thread length is often needed.

Doing this can prevent the higher expense of stainless steel.

- It offers superior corrosion resistance to a lot of petroleum items.

- It resists corrosion in non-oxidizing acids. However, oxidizing acids should be prevented.

- It usually deals with exposure to mild alkaline solutions. However, strong solutions such as cyanides and hydroxides must be prevented.

- It works well in those cryogenic uses. That makes it an excellent substitute for 300 series stainless steel in some cases.

- Nickel-plated brass is also great for cold and hot-water residential or industrial systems.

That includes those that carry potable water.

But the brass material is easier to break and with lower anti-crossing function in outdoor applications.

How About Stainless Steel Cable Glands?

You are already aware that stainless steel is accessible in a plethora of varieties.

Austenitic stainless steel or 300, series is the most widely utilized for inserts.

You see:

The properties of stainless steel hex cable glands differ substantially from one family or alloy to the next.

What’s more:

Making general statements about its performance is hard.

Austenitic stainless steel rod in the workshop

Most of all:

The many ones-of-kind values presented by stainless steel make it a strong candidate in materials selection.

Designers, specifiers, and engineers frequently underestimate or ignore such values.

That’s because of what is seen as the higher initial expense of stainless steel.

Nevertheless, over the entire life of a project, stainless steel is always the best value option.

Here’s why:

- Did you know that austenitic stainless steel, a particular type of stainless steel – offers a higher service temperature compared to nickel-plated brass? It is crucial to take note that this gives limited benefit due to the heat deflection temperature of the plastic component.

- Particular grades of 300 series stainless steel like 316, 304, and 302 are FDA-approved for food contact. That only means that it’s a perfect option for food and beverage use. Plus, free-machining 303 stainless steel isn’t permitted for use in contact with food.

- Stainless steels are commonly stronger than nickel-plated brass.

- Superior resistance to many acids and petroleum products.

It could be passivated in either nitric or citric acid solutions.

However, you need to stay away from hydrochloric acids.

The stainless steel cable gland is water-proof.

- Particular grades like 316 stainless steel are greater than brass in harsher marine settings like fast-moving currents.

However, this doesn’t apply to every grade.

The most typical turning stainless includes further sulfur which enhances machinability compared to other 300 series stainless sheets of steel.

On the other hand:

Sulfur substantially lowers corrosion resistance in the seawater.

Slow-moving seawater or brackish might also boost pitting or crevice corrosion in several grades.

Why Choose Stainless Steel Cable Gland?

- Long-Term Value

If total life cycle expenses are considered, the stainless steel cable gland is often the least costly material option for you.

Stainless steel cable gland in electrical equipment

- Impact Resistance

Another reason why it’s better to opt for a stainless steel cable gland is that it offers toughness.

From far below freezing to elevated temperatures, the austenitic microstructure of the 300 series makes such steels fitted to cryogenic uses.

- Aesthetic Look

Its bright, easily maintained surface offers an attractive and modern look.

- Heat and Fire Resistance

Special nickel-alloyed and high chromium grades resist scaling and keep strength at high temperatures.

- Corrosion Resistance

Ultimately, last but not least:

Stainless steel cable glands fight corrosion in pure water and atmospheric settings.

On the other side of the story:

Alloyed grades can repel corrosion in the majority of:

- chlorine bearing environments

- alkaline solutions and;

- acids

properties that are employed within process plants.

Chapter 3: Stainless Steel Cable Gland Applications

From the tiniest zipper to the biggest skyscraper, stainless steel cable glands are a crucial part of modern life.

It’s strength, low maintenance, waterproofing, and corrosion resistance make it the perfect material for a wide array of applications.

What’s more:

It has a long life cycle and is considered entirely recyclable.

Did you know that there are more than 150 grades of stainless steel?

All of which fifteen are typically utilized in day-to-day applications.

1. Food and Beverages

The stainless steel cable gland is utilized in kitchen accessories, cookware, and cutlery.

From surfaces to tools, this metal is exceptionally appropriate for:

- production

- processing as well as;

- packaging

The machinability and waterproof properties of stainless steel and other properties make it a perfect alternative for food processing.

2. Minerals and Mining

The mining sector is one where Stainless steel armored cable gland has made it simpler and more lucrative to take on bigger operations.

It is utilized in the actual mines where machines and workers dig at the earth.

It can also be used in the bunk beds and mess halls where the staff sleep.

You see, it’s utilized in a wide array of applications to offer reliability and safety.

Stainless steel cable gland in explosion-proof equipment

3. Automotive

Cars are making massive utilization of stainless steel, mainly for exhaust systems and catalytic converters.

Along with proper attention being made to accomplishing low long-term maintenance expenses, higher concern with life cycle expenses, and less environmental effect, the market for Stainless steel breathable cable glands continues to increase.

4. Construction, Architecture, and Building

Construction, architecture, and the building is a growing market.

That’s because a myriad of modern buildings employ Stainless steel EMC cable glands for cladding.

Another thing here is the anti-vandal and low-cost characteristics of stainless steel offer a massive market in:

- street furniture

- ticket machines and;

- public transport

Stainless steel is also utilized for construction purposes.

Stainless steel cable gland m20 and m18 stainless steel cable glands are commonly used in these applications.

5. Pharmaceutical Applications

The employment of Stainless steel double compression cable glands is wide within the pharmaceuticals sector because of their:

- ease of fabrication

- inert surfaces

- waterproof

- resistance to corrosion

Stainless steel cable gland in machine

Even though AISI 316, as well as its derivatives, are the most utilized in a pharmaceutical plant, materials for every application are chosen according to their resistance to corrosion.

The selection of the appropriate grade of stainless steel should include the deliberation of the cleaning agents and cleaning regime utilized in the plant.

6. Marine and Shipping

Materials for marine uses are chosen to keep the integrity of the structure.

An example of this is it must be robust enough to endure their service environment.

They must be corrosion-resistant and waterproof as well.

Stainless steel marine cable gland is utilized in many marine applications such as:

- shipping and;

- water shore drilling

Stainless steels are being used in marine application as they are:

- easily fabricate

- resistant to any corrosion and;

- provide excellent mechanical properties

M12 stainless steel cable gland is the standard stainless steel cable gland size used in the industry.

7. Processing, Chemical, and Gas & Oil Industries

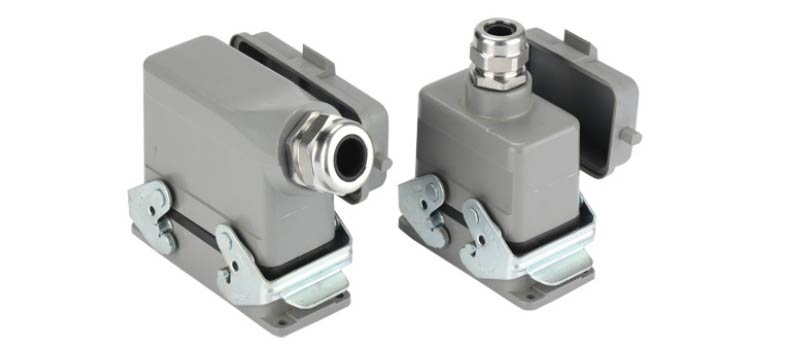

Stainless steel cable gland in heavy-duty connector

Perhaps the most challenging industries which employ stainless steel are the:

- the oil and gas industries

- processing industries and;

- chemical industries

They’ve made a massive market for stainless tanks, valves, pumps, and pipes as well.

Special types of stainless have been made to have higher corrosion resistance at a wide array of various temperatures.

Those are employed in:

- ships propellers

- harbor supports

- offshore oil rigs

- sewage plants and;

- desalination plants

That is where the use of Stainless steel explosion-proof cable glands is very beneficial.

8. Lighting Fixture

The stainless steel cable gland is widely used in LED lighting fixtures, with the most popular sizes ranging from M8 to M20.

Sometimes, the outdoor LED lighting fixture needs SS316L standard stainless steel cable gland because of the higher anti-corrossion performance, especially in the coastal area, SS304 material may become rusty after long time among the sea breeze.

Chapter 4: Stainless Steel Cable Gland Market

The cable gland is a mechanical cable entry module that facilitates barrier penetration and offers to seal.

They’re also famous for strain relief.

In this chapter, we will provide you with some useful information about the market for stainless steel cable glands.

The cable glands market produced a revenue of $1,667 million last 2016 and is estimated to reach $2,513 million in 2023.

Last 2016, the armored segment is expected to increase at the highest rate throughout the forecast time.

The global stainless steel cable glands are segmented by type into hazardous and industrial.

The market is also categorized by cable type into:

- armored;

- unarmored

The market is classified further by different material that includes:

by material:

- Stainless Steel Type 201

- Stainless Steel Type 304

- Stainless Steel Type 316

by protection:

- IP67 stainless steel cable gland

- IP68 stainless steel cable gland

- IP69 stainless steel cable gland

and by the end-user into:

- manufacturing & processing

- aerospace

- oil and gas

- chemical and;

- others

Its evaluation across four geographical regions includes:

- USA

- Australia

- UK

- Singapore

- India

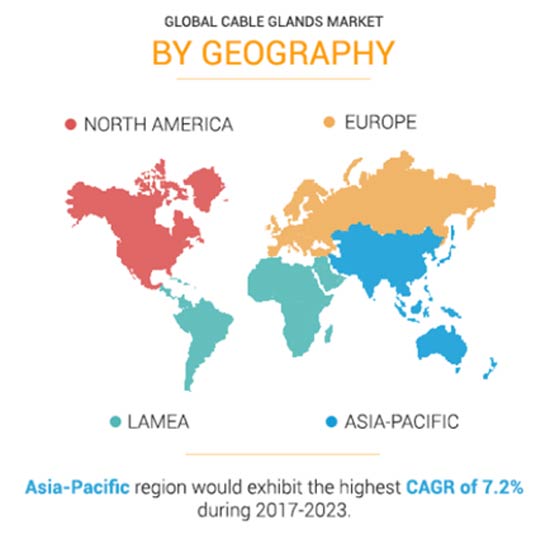

Global Cable Glands Market Share, by Geography

Photo Courtesy: Allied Market Research

In the report, Asia-Pacific is considered to be one of the fastest expanding economic regions around the world.

In fact:

- Japan

- India and;

- China

are some of the nations, growing at a substantial rate when it comes to the economy.

What’s more:

Asia-Pacific is wealthy in chemicals, refineries, and mines.

Thus, the implementation of industrial tools such as stainless steel cable glands has seen a massive development within the region.

What’s more, Asia-Pacific accounted for the maximum revenue share in 2017.

That’s because of the improved demand for stainless steel material followed by Europe in the top 5 countries that contributed billions of revenue in 2017.

You see, stainless steel is widely utilized in different applications as mentioned earlier.

Recovery of the stainless steel sector in the developed countries of Europe and North America in more than two years has been a massive driving force for the growth and progress of the industry.

Furthermore:

The increase of mining and mineral, trains, submarines, ships, and the tanks is expected for commercial and industrial constructions in emerging nations like:

- Brazil

- India and;

- China

That strong economic development combined with the industrial industry is anticipated to boost market growth over the forecast time.

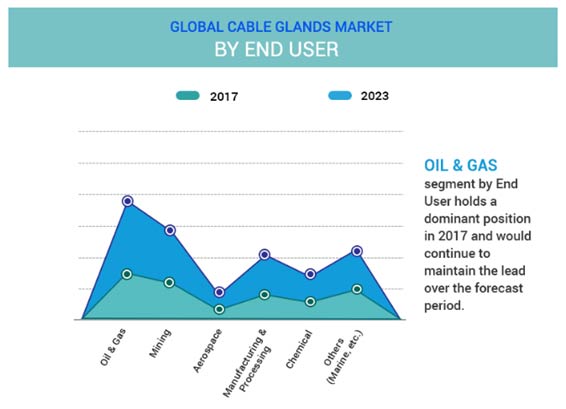

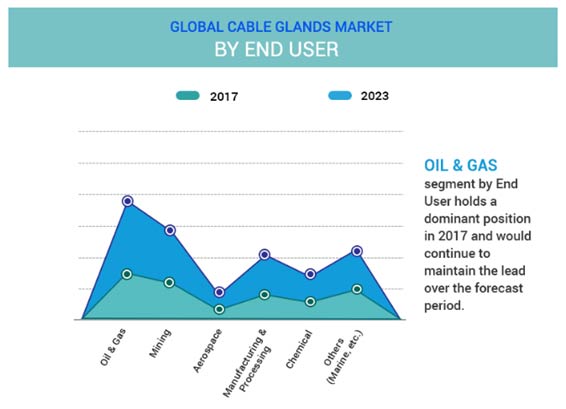

Global Cable Glands Market Share, by End User

Photo Courtesy: Allied Market Research

The audits, ordination, and acid tests performed in 2016 have anticipated greater profits for the oil and gas sector along with low-cost feedstocks.

They also have an increase in some projects showing development in technology.

You see, refineries within the LAMEA and Asia-Pacific regions concentrate on boosting the production of:

- gasoline

- diesel and;

- jet fuel

along with the extensive use of cutting-edge methods.

Aside from that:

New automation in extracting or processing natural gas as well as recasting it into other hydrocarbons is projected in the future years.

With this in mind, safety has massively become crucial for oil and gas plants’ survival in the current market.

Therefore, the usage of stainless steel cable glands is on the upsurge.

That’s because they have now become the primary means of safety from uncertain and hazardous environments around the world.

Stainless Steel Market Share, by Material

Photo Courtesy: Grand View Research Inc.

Properties like:

- aesthetic look

- tensile strength and;

- corrosion resistance

make stainless steel a critical raw material within the automobile industry.

It’s utilized within the manufacturing of components like exhaust systems, hose clamps, and springs.

The superior formability and weldability features have facilitated its high usage in lightweight vehicles.

Grades 316, 304, and 303 are used in heavy industry and construction applications because of their corrosion resistance property.

Conclusion

You could tell that stainless steel cable glands have a lot going for them.

Apart from its resistance to staining and corrosion as well as waterproof properties, the majority of stainless steel items in the market have a long lifespan.

In fact, on average, stainless steel items like:

- exhaust systems

- pressure vessels

- tubing

- saucepans

- cutlery

- counter-tops and;

- cable glands

can be anticipated to last for fifteen to twenty-five years.

However, for some applications, that number is much higher.

So, there you have it!

The future of stainless steel cable glands is most surely bright as remarkable innovations involving the material come to the fore.

While you might not be able to foresee the future, we do produce and fabricate a wide array of cable glands including stainless steel for use across a wide variety of industries or purposes.

If you have a particular project in mind, we would love to guide you to turn it into a reality!

What’s more, we are your #1 waterproof stainless steel cable gland manufacturer to help you supply with high-quality stainless steel cable glands.

For more information, call us and talk to one of our friendly team of specialists today.

What are your thoughts about this e-book?

Share your thoughts with us by sending your comments!

We’d love to know about your ideas too!